Is often purchased together with

You might also be interested in

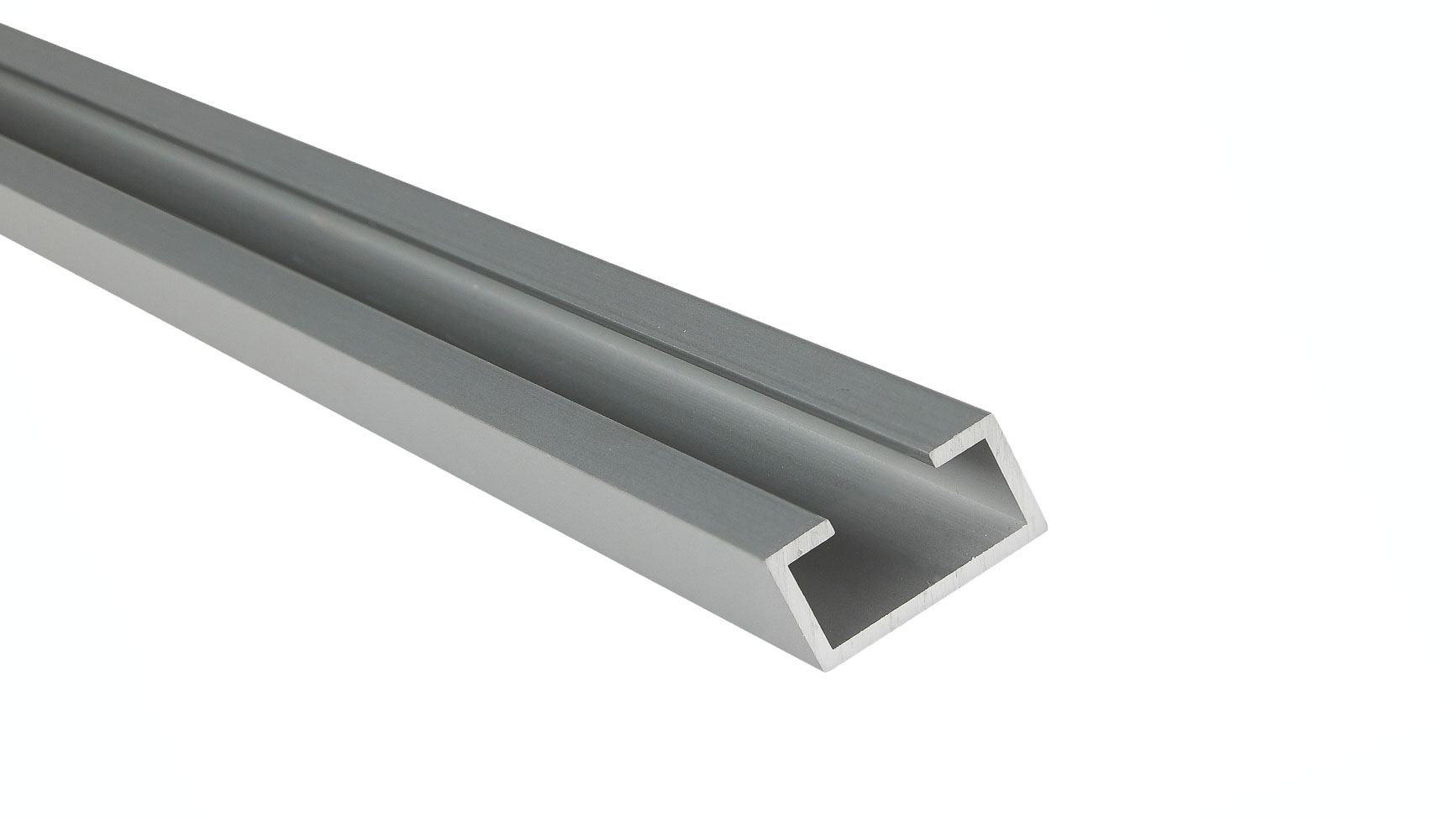

Product information

- Surface: silver anodised E6/EV1

- Material: AlMgSi0.5

- Material number: according to EN AW-6060

- E6: chemically pre-treated, anodised and compacted. A matt surface is produced.

- EV1 is a standard process for anodising, whereby a silver-coloured natural anodised layer is produced.

- Surface thickness: 10 my

- Manufacturing process: pressed

- Standard: EN 573-3, 755/-1/-2/-3/-4/-5/-8/-9

The sawn edges are not anodised, unfinished and not deburred. In addition, scoring, scratches etc. in the raw product cannot be completely covered by anodising and may also remain visible.

Nevertheless, we always endeavour to supply all blanks in the best quality.

Product properties:

- low density

- Ideal for powder coating

- Very good corrosion resistance

- Low dimensional tolerances

- good machinability

- cannot be magnetised

- Can be decoratively anodised very well

- Good weldability and solderability

- Suitable for use in the food sector in accordance with EN 602

Due to their practical properties, aluminium C-profiles can be used in a wide range of applications. As a multi-profile, they are suitable for the construction of milling tables, work aids, stops or as a rail system, for example. The anodised surface offers the best sliding properties here. With this profile, an M8 screw head or M8 nut can be inserted and freely positioned. The screw can then be fixed in any position using a handwheel. This makes it very easy to build sliding stops or many other work aids.

Our C-profiles are available in anodised and powder-coated finishes. If you have any special requirements for your aluminium C-profile, please contact us!

Note: This information only applies if you have selected the powder coating option in the configurator when placing your order.

Powder coating - additional information and quality features

Surface features and properties:

- Surface: powder-coated for an even, robust protective layer

- Coating thickness: 60 - 80 µm for optimum protection and durability

- Reflectometer value (gloss level):

- Glossy: 80 - 95

- Matt: 20 - 30

Powder-coated aluminium C-profiles - ideal protection and aesthetics

Powder-coated aluminium C-profiles offer a high-quality protective coating and a smooth, even surface. These profiles are particularly suitable for applications that require both high corrosion resistance and an attractive appearance, for example in the construction industry, mechanical engineering and furniture production. Thanks to the powder coating, these C-profiles are extremely durable and available in a wide range of surface finishes. In our range you will find a wide selection of powder-coated, anodised and bare aluminium C-profiles in various sizes and dimensions. If you have special requirements for powder coating or customised dimensions, we will be happy to help you select the right product for your project.

Note: The surface quality and colour of our powder-coated aluminium C-profiles may vary slightly depending on the production batch. Colour deviations are also possible due to monitor and graphic settings.

Layer formation during powder coating

Powder coating is carried out by a high-voltage cascade that generates a high voltage in the gun body at the nozzle tip (electrode). An electric field is created between the earthed workpiece and the electrode, which charges the paint particles negatively. These paint particles are finely distributed in a uniform spray cloud and are deposited evenly on the surface of the aluminium C-profiles. The electrical charge also traps excess powder in the field, which ensures a complete and even coating around the workpiece. The coating thickness is often thicker at the edges - this picture frame effect is advantageous for corrosion protection, but may require careful reworking for tight fits.

Powder coating - quality requirements

For the quality inspection of powder-coated aluminium C-profiles, the coated surface must not show any blisters, craters, pinholes or scratches when viewed with normal or corrected vision and at a distance of 3 metres (for indoor applications) or 5 metres (for outdoor applications). The coating should be free from damage that penetrates through to the metal. Deviations in the primary material that occur during the pressing process do not affect the quality of the powder-coated surface and therefore do not fall within the scope of assessment

Please note that the ordered product may differ from the product images in terms of the surface finish due to different production batches. The same applies to colours, which are displayed differently depending on the monitor and graphics card.