Is often purchased together with

You might also be interested in

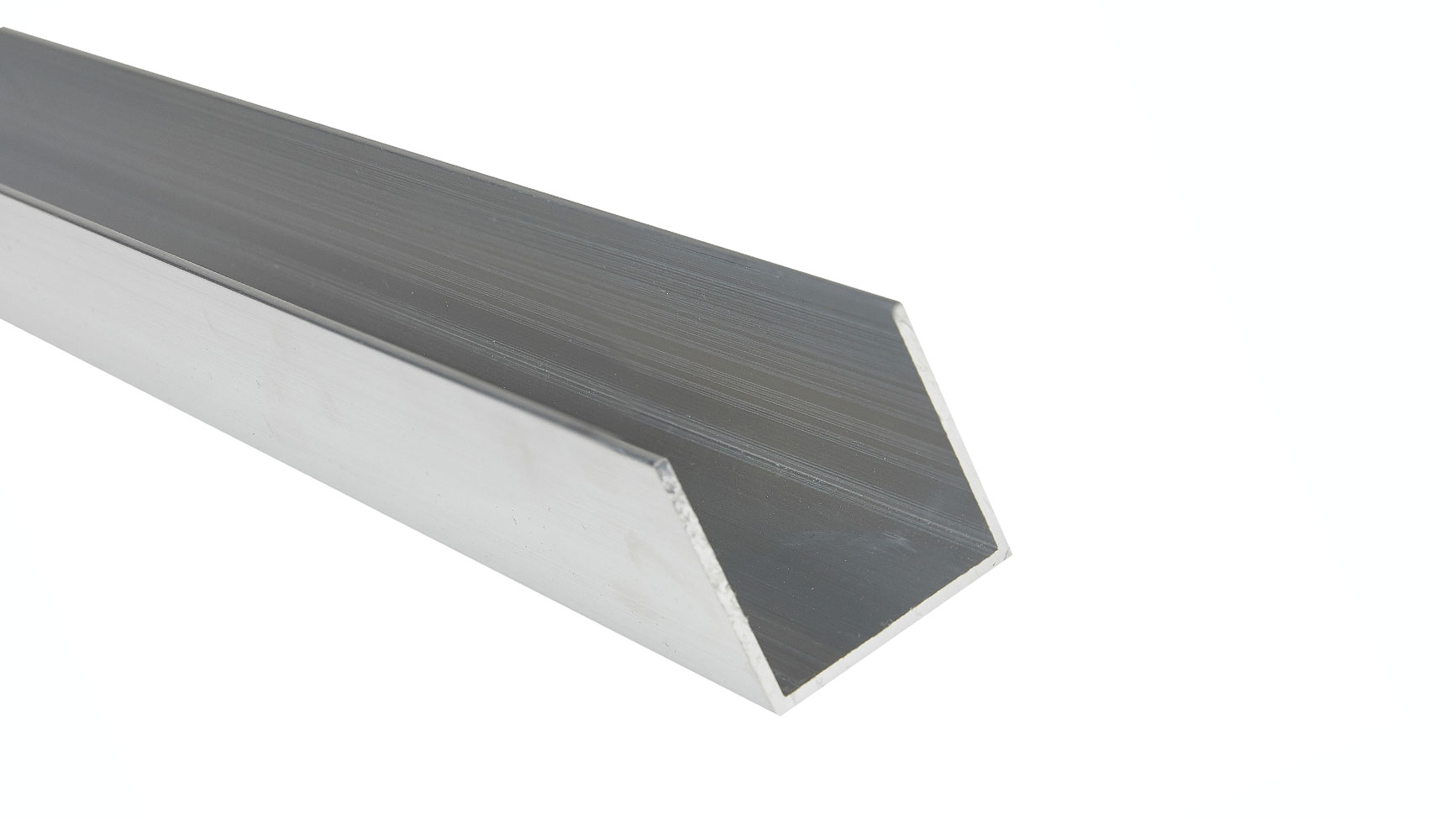

Product information

- Surface: bright/raw

- Material: AlMgSi0.5

- Material number: according to EN AW-6060

- Delivery condition: T66 solution annealed and artificially aged

- Manufacturing process: pressed

- Standard: EN 573-3, 755/-1/-2/-9

- Wall thickness tolerance: +-0.25 mm (this means that the internal dimension can be 0.25 mm smaller or larger)

The sawn edges are unfinished and not deburred. The surface is raw/bright, so scratches etc. cannot be avoided; this is normal in the trade and is no reason for complaint. Nevertheless, we always endeavour to supply all cut-to-size pieces in the best quality.

Product properties:

- low density

- ideal for powder coating

- Very good corrosion resistance

- low dimensional tolerances

- good machinability

- cannot be magnetised

- Can be decoratively anodised very well

- Good weldability and solderability

- Suitable for use in the food sector in accordance with EN 602

Aluminium U-profiles are lightweight and easy to process. To make them particularly resistant to weathering, they can be finished by anodising or powder coating. Once they are finished and weather-resistant, they are particularly suitable as a universal construction element for building fences - but also in interior fittings for doors and partition walls. They also serve as a basic element in drywall construction, in industry or in machine and plant construction. Due to their properties, they can be used in almost all areas of industry and trade.

You can choose from blank, anodised and powder-coated as well as many different dimensions for your U-profile. Simply select the dimensions and surface finish in our online configurator and our experts will take care of everything else. If you have any questions about special sizes or other special requests, we look forward to receiving your enquiry.

Note: This information only applies if you have selected the powder coating option in the configurator when placing your order.

Powder coating - additional information and quality features

Surface features and properties:

- Surface: powder-coated for an even, robust protective layer

- Coating thickness: 60 - 80 µm for optimum protection and durability

- Reflectometer value (gloss level):

- Glossy: 80 - 95

- Matt: 20 - 30

Please note: There are approx. 5 mm holes at the ends of our powder-coated aluminium U-profiles, which are used for fixing during the coating process and are untreated and not deburred. To minimise untreated ends, in many cases we manufacture without holes or only with holes on one side. For precision applications, we recommend an allowance of around 50 - 80 mm.

Powder-coated aluminium U-profiles - ideal protection and aesthetics

Powder-coated aluminium U-profiles offer a high-quality protective coating and an even, attractive surface. They are ideal for applications that require both high corrosion resistance and an aesthetic appearance, such as in the construction industry, the automotive industry and for decorative purposes. Thanks to the powder coating, the aluminium U-profiles are durable and available in various surface finishes. Our range includes a wide selection of powder-coated, anodised and bare aluminium U-profiles in various sizes and dimensions. We will be happy to advise you on special powder-coating requirements or customised dimensions.

Note: The surface quality and colour of our powder-coated aluminium U-profiles may vary depending on the production process. Colour deviations are possible due to monitor and graphic settings.

Layer formation during powder coating

In the powder coating process, a high-voltage cascade in the gun body generates a high voltage at the nozzle tip (electrode), which creates an electric field between the earthed workpiece and the electrode and charges the paint particles negatively. These particles are distributed in a uniform spray cloud by mutual repulsion and are deposited all around the surface of the aluminium U-profiles. The electric field also causes excess powder to adhere to the back of the workpiece, ensuring a complete coating. A thicker layer often forms on edges - this so-called picture frame effect improves corrosion protection, but may require reworking if the fit is tight.

Powder coating - quality requirements

When assessing the quality of powder-coated aluminium U-profiles, the coated surface must not show any blisters, craters, pinholes or scratches when viewed with normal or corrected vision and at a distance of 3 metres (for indoor applications) or 5 metres (for outdoor applications). The coating should be free from damage that exposes the metal. Deviations in the primary material caused by the pressing process do not affect the quality of the powder-coated surface and are excluded from the quality inspection.

Please note that the ordered product may differ from the product images in terms of the surface finish due to different production batches. The same applies to colours, which are displayed differently depending on the monitor and graphics card.